VERTICAL CENTERS

The widest range of vertical drilling and milling/grinding machines in the world

Contact us now +39 0296979011

Contact us for more infos

Quickdrill

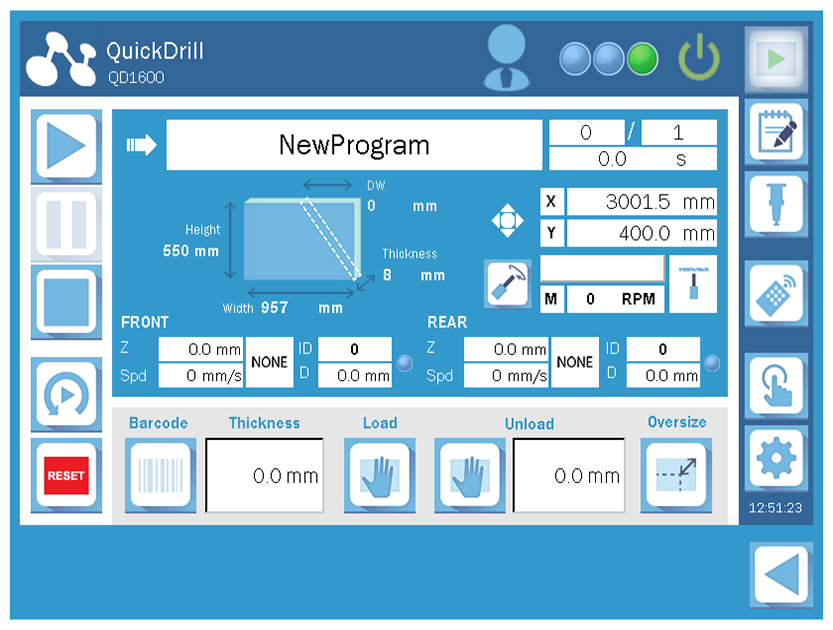

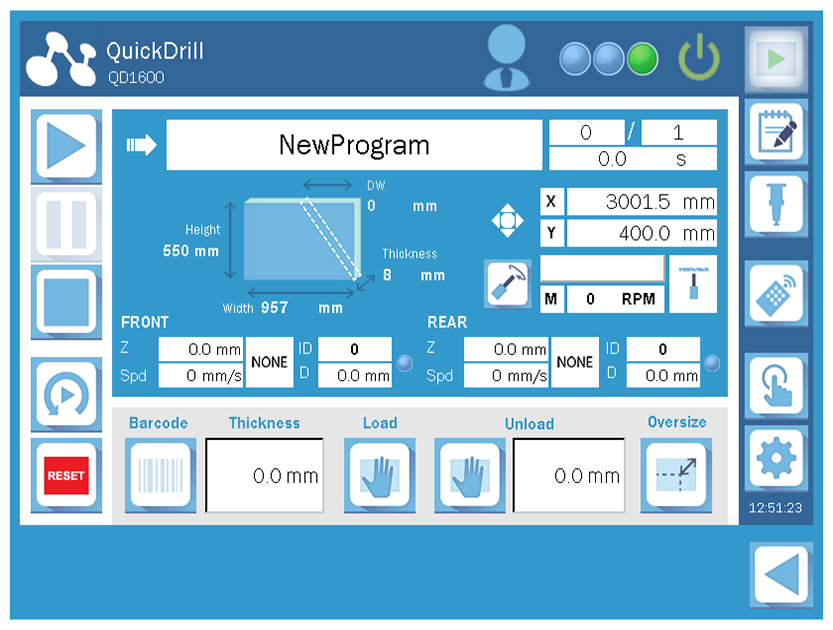

The entry-level Numerical Control drill, built with a solid structure for industrial use and guided by a powerful and intuitive software. The tool change is manual, facilitated by the spindle lock. It is therefore suitable for glass factories that have less pressing production and automation needs, that process small series of glass and tend to have one or a few holes of different diameters on the same glass plate.

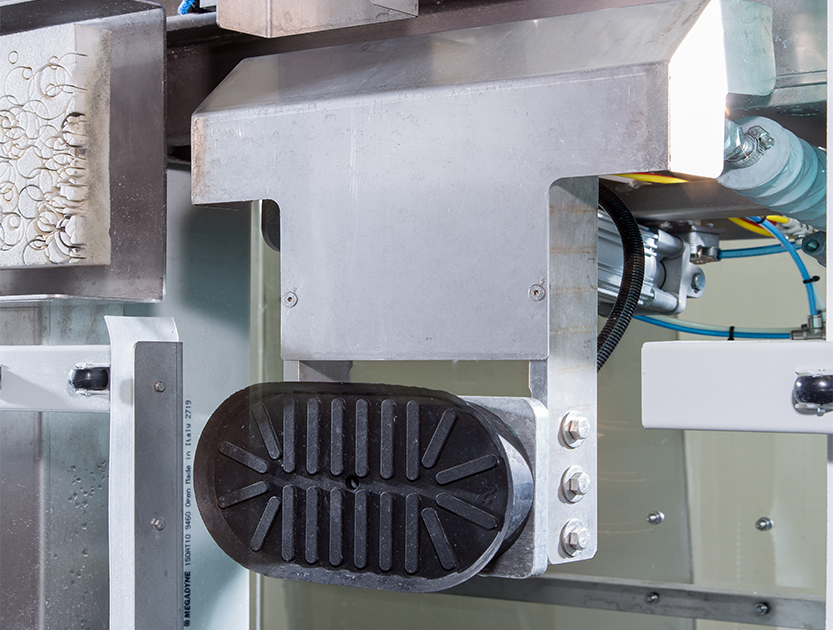

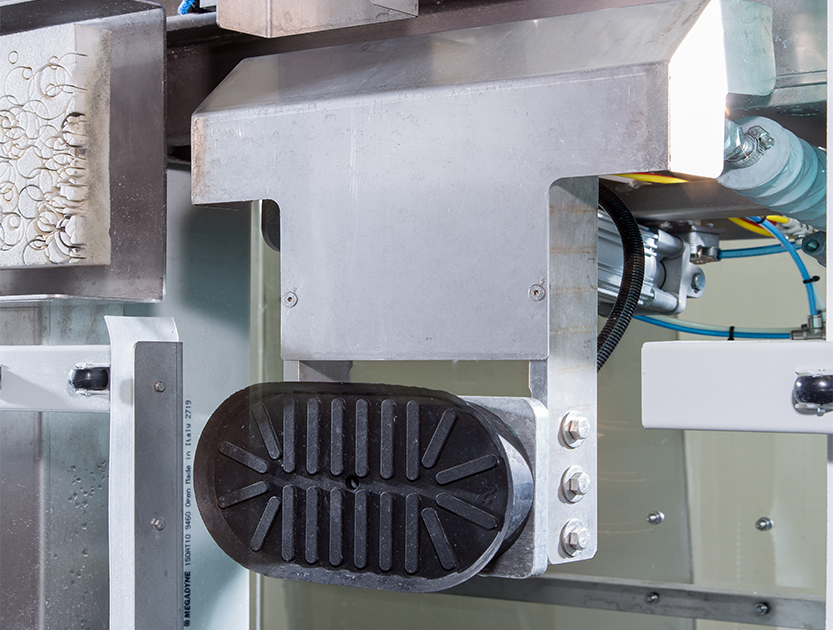

Very precise glass positioning (+/- 0.15 mm) and constant over time thanks to the transport clamp controlled by linear encoders

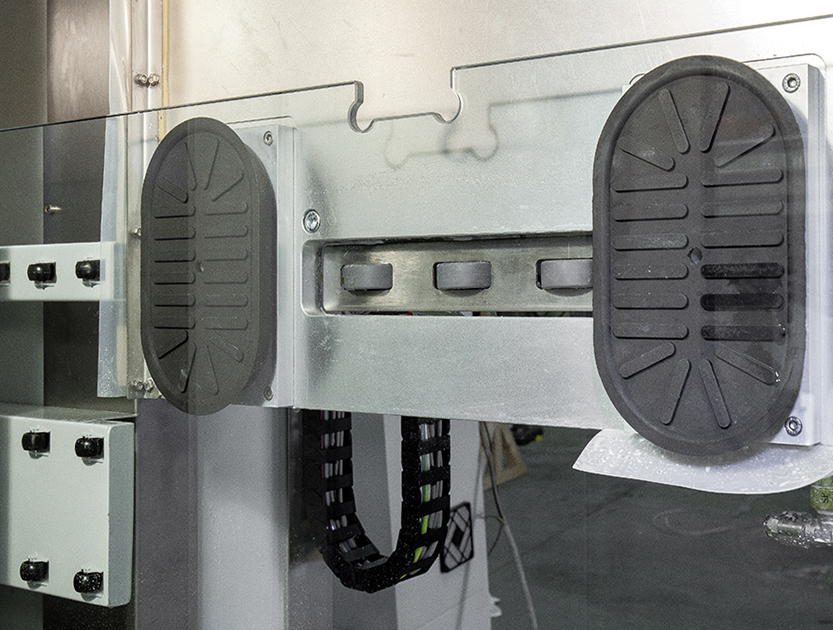

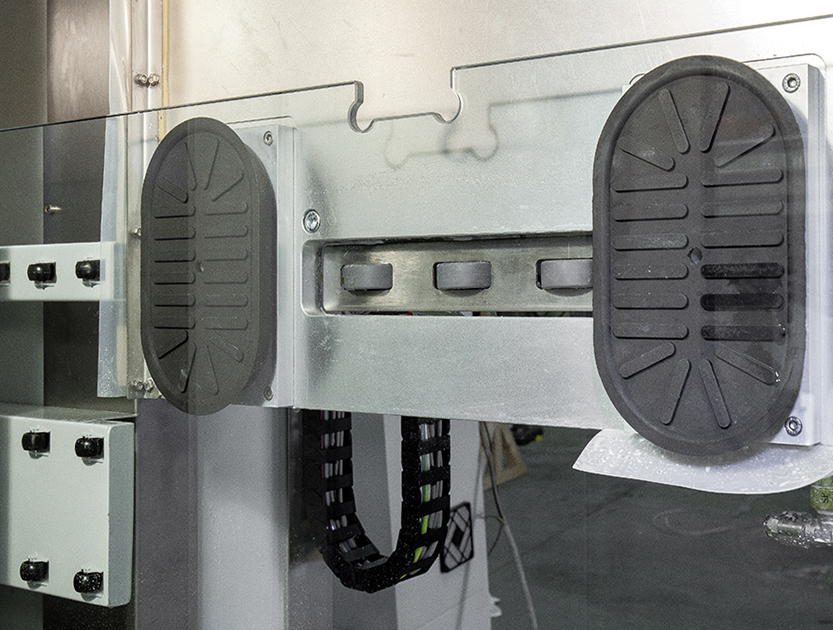

Reduced risk of glass breakage thanks to the spindles with hydropneumatic ‘cushion’ system on the Z axis, which adapts the penetration speed based on the cutting edge of the core

Extensive use of stainless steel and perfect water containment, together with the construction details, make it almost free from maintenance costs

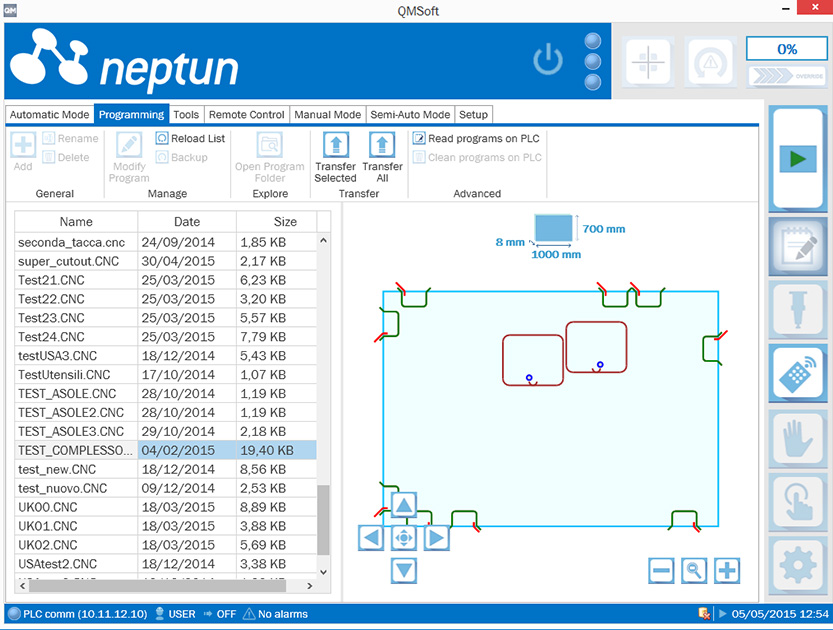

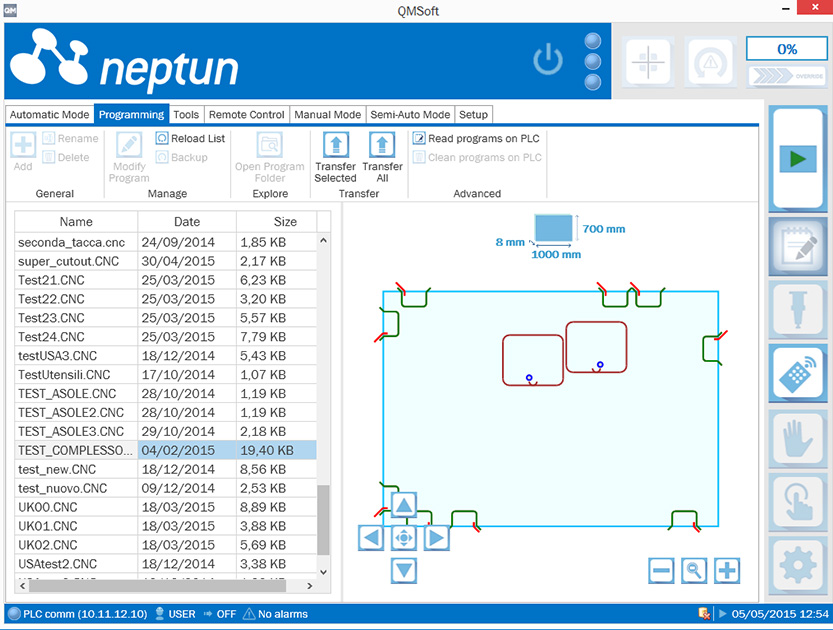

Powerful and intuitive software that facilitates the operator’s work thanks to the ‘drag & drop’ system of thousands of parametric shapes. Also very useful are the ‘nested program’ functions, which allows you to recall a program and repeat it ‘n’ times, having defined the step, and the ‘double zero’, thanks to which the out-of-square shapes can be programmed by choosing between 2 different references with absolute or relative coordinates.

Very precise glass positioning (+/- 0.15 mm) and constant over time thanks to the transport clamp controlled by linear encoders

Reduced risk of glass breakage thanks to the spindles with hydropneumatic ‘cushion’ system on the Z axis, which adapts the penetration speed based on the cutting edge of the core

Extensive use of stainless steel and perfect water containment, together with the construction details, make it almost free from maintenance costs

Powerful and intuitive software that facilitates the operator’s work thanks to the ‘drag & drop’ system of thousands of parametric shapes. Also very useful are the ‘nested program’ functions, which allows you to recall a program and repeat it ‘n’ times, having defined the step, and the ‘double zero’, thanks to which the out-of-square shapes can be programmed by choosing between 2 different references with absolute or relative coordinates.

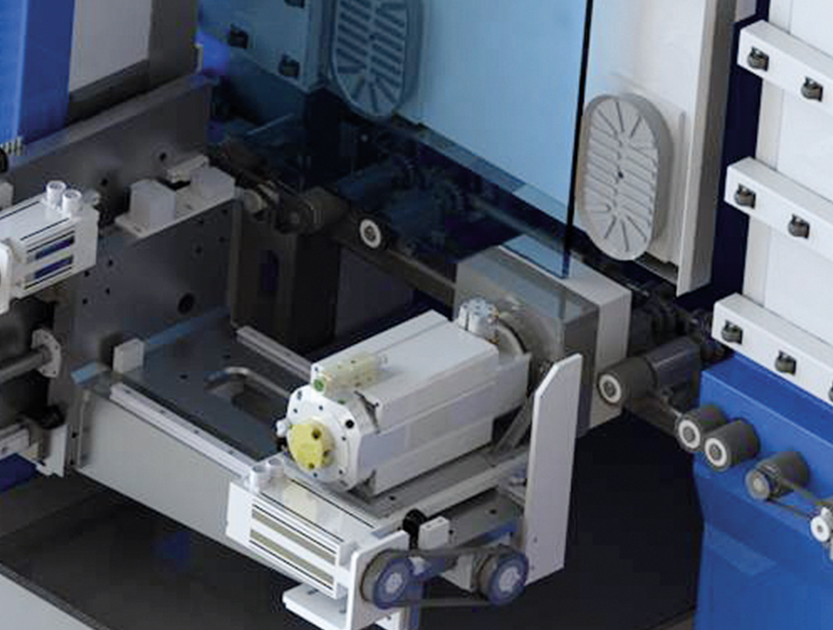

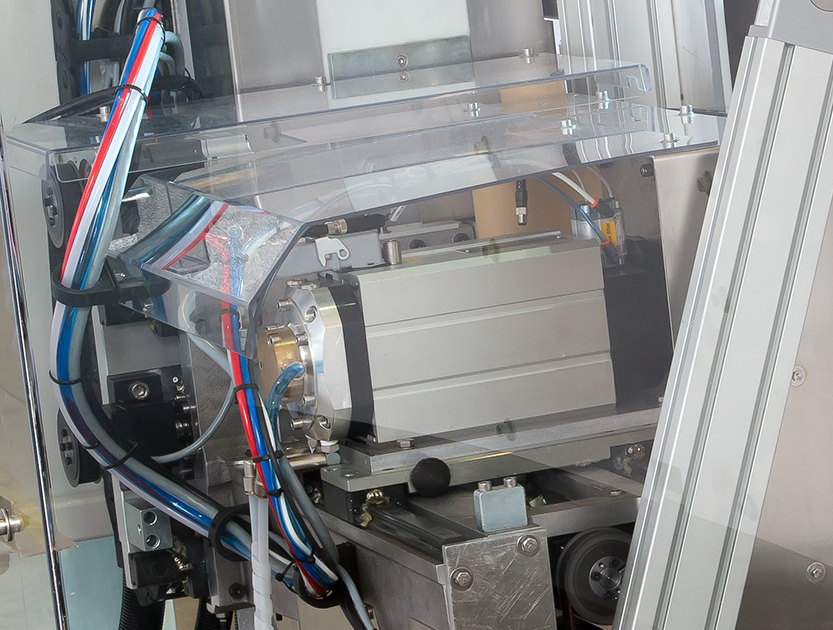

Quickdrill-T8

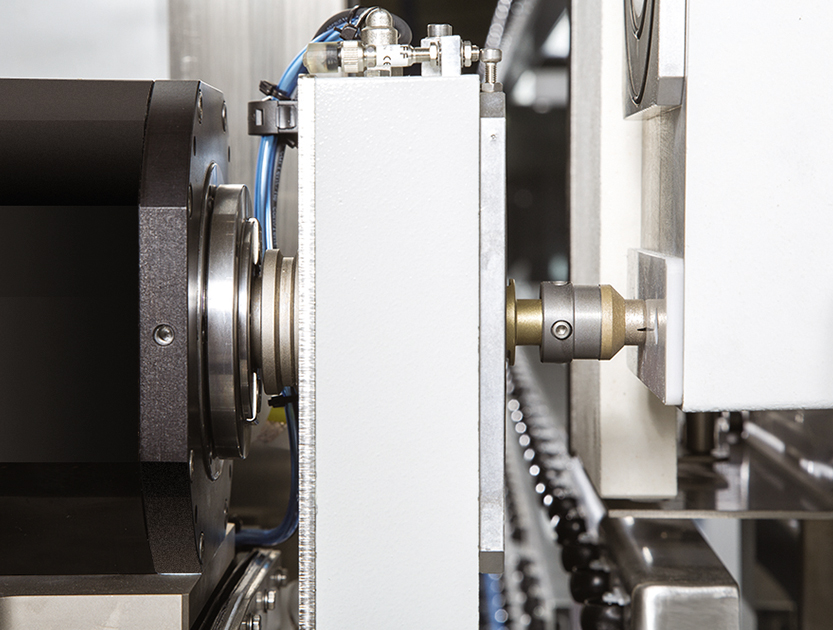

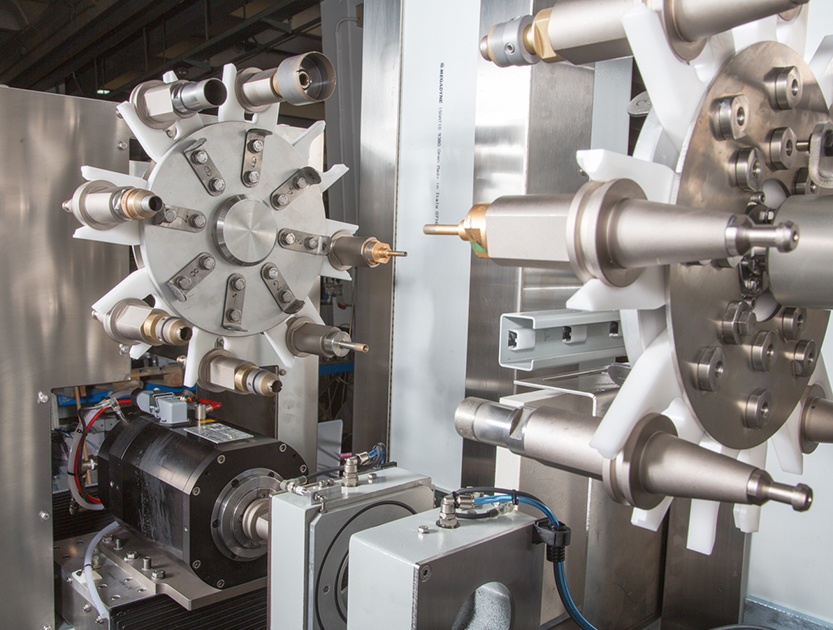

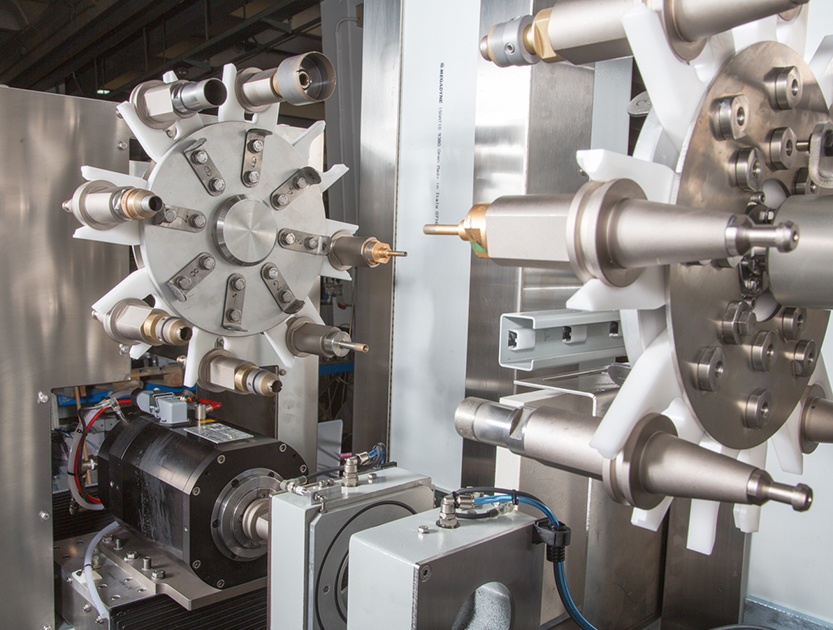

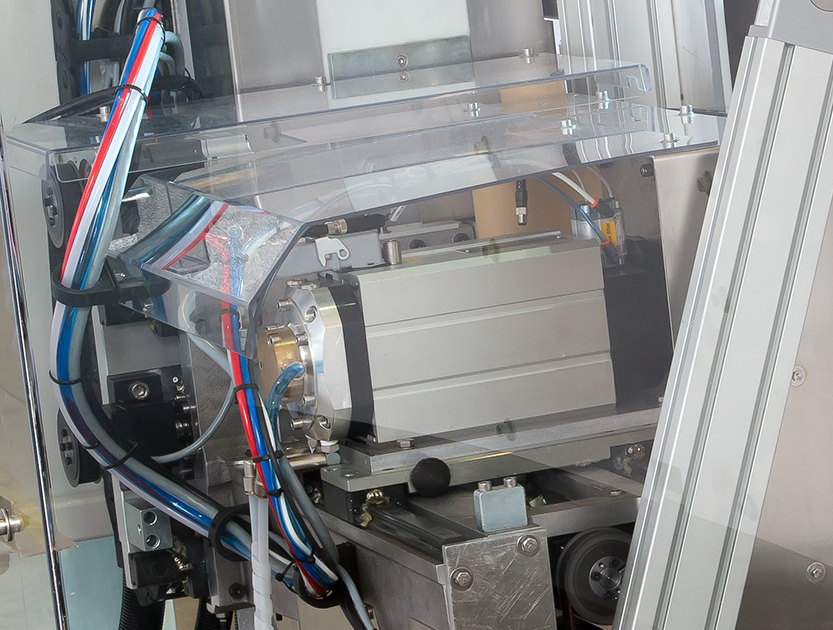

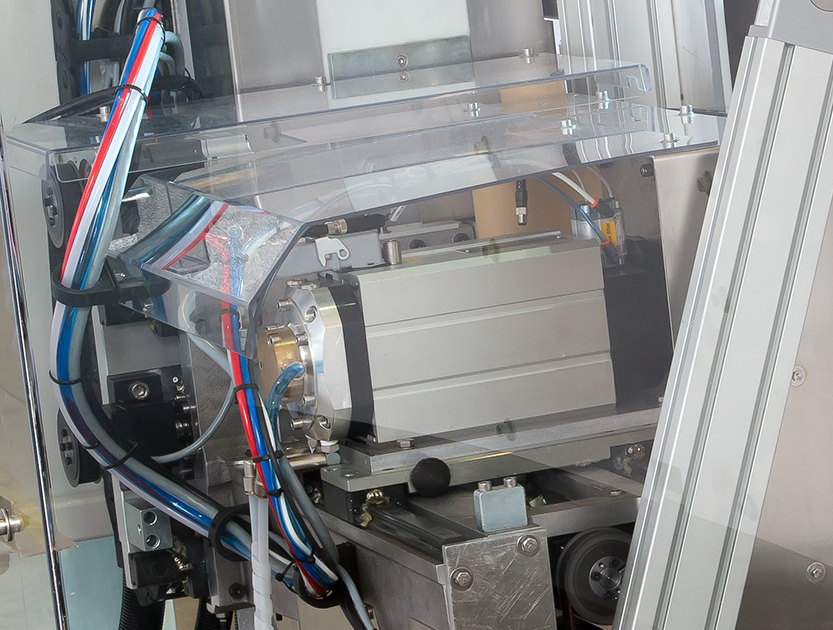

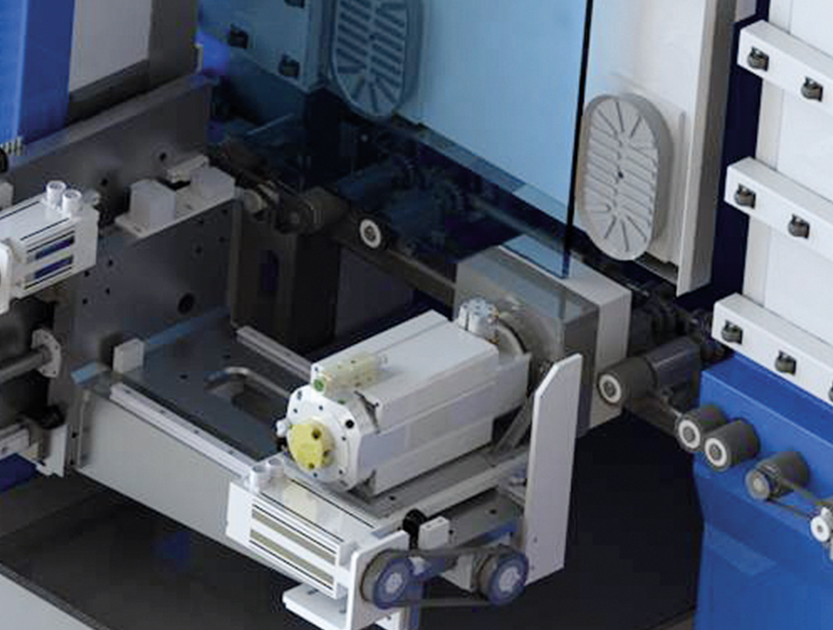

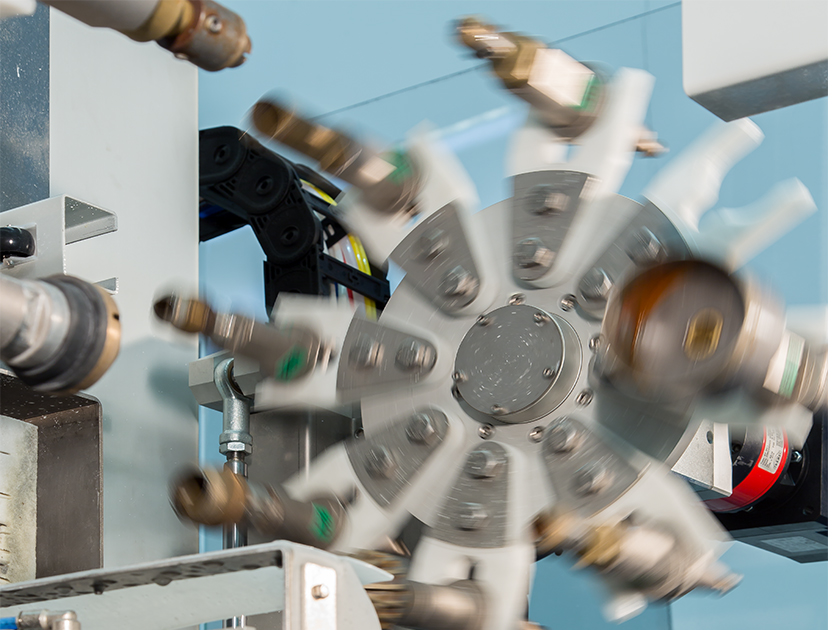

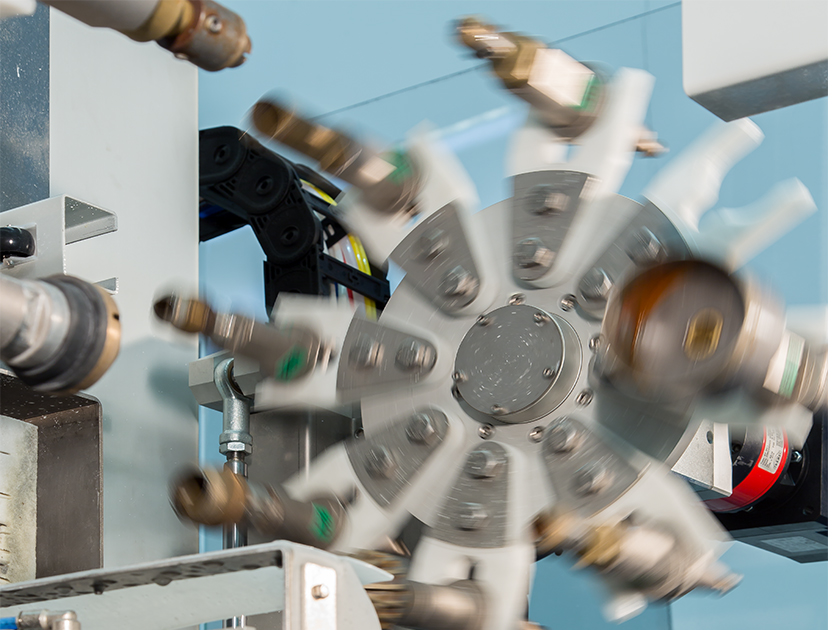

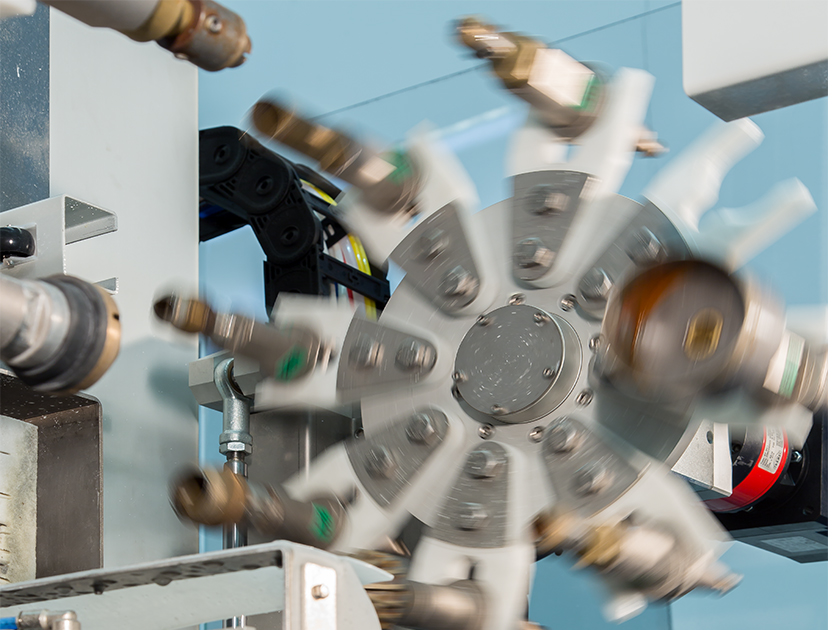

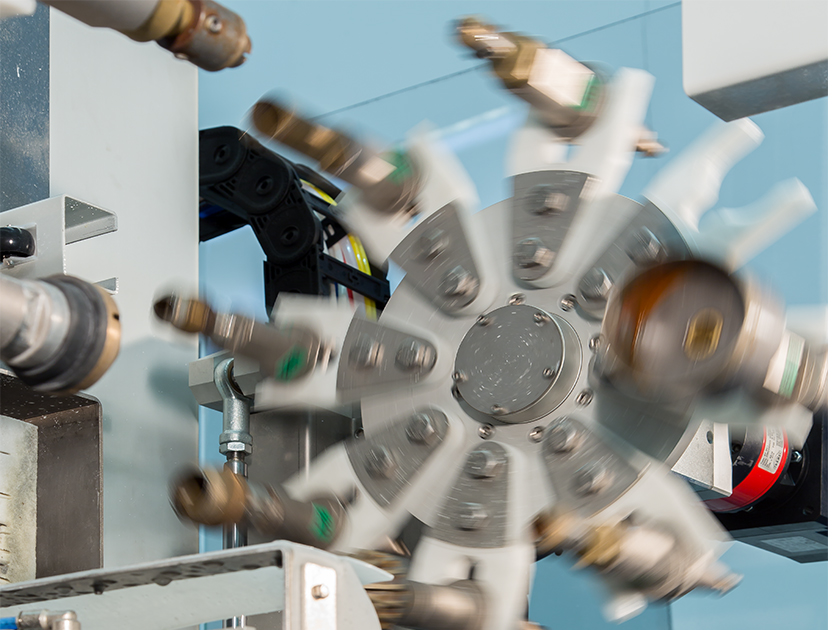

The top of the market for drilling and milling with surprising performance and reliability. Ideal for glassworks with very intense work cycles, with the possibility of integration with loading and unloading robots, and where sudden machine downtime is not tolerated. Equipped with a double rotary tool holder with 8 + 8 positions directly mounted on the drilling spindle, it allows simultaneous tool change and axis positioning in less than 8 seconds.

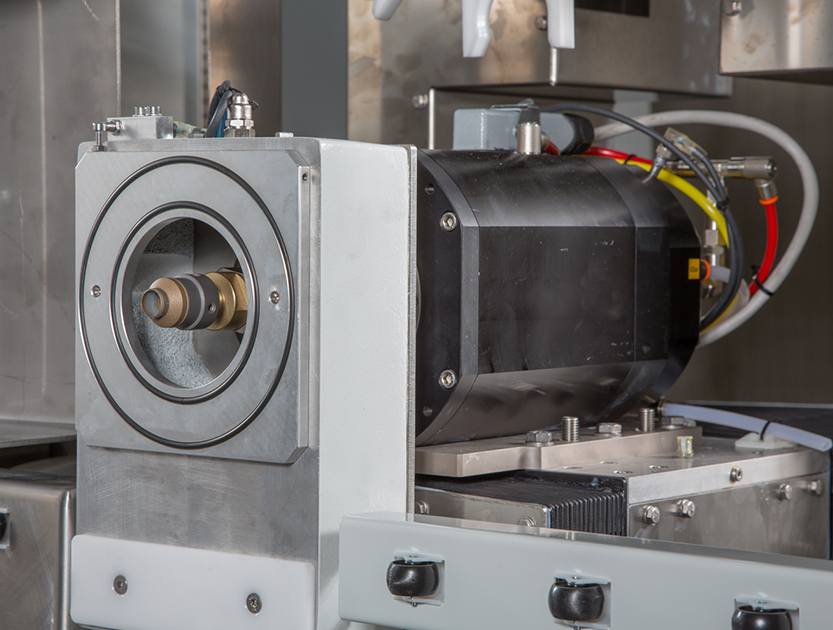

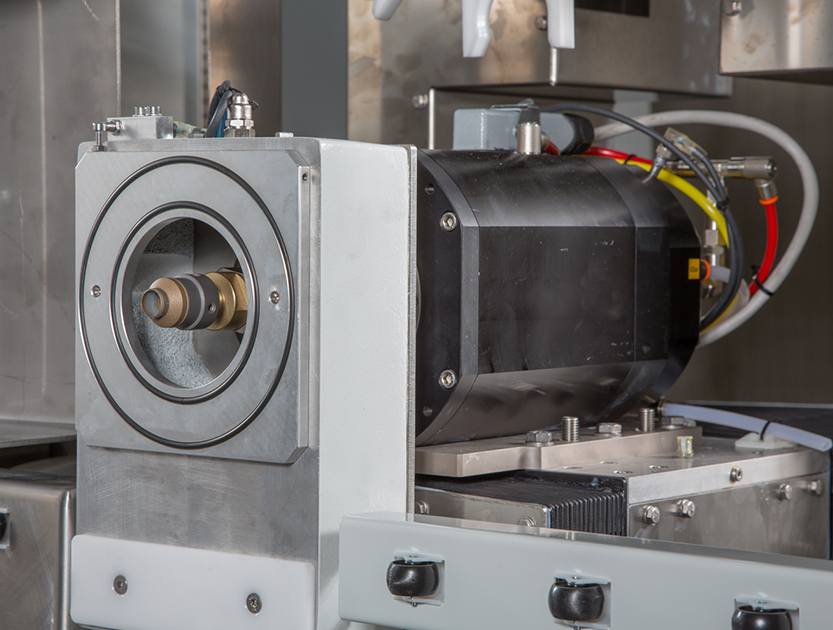

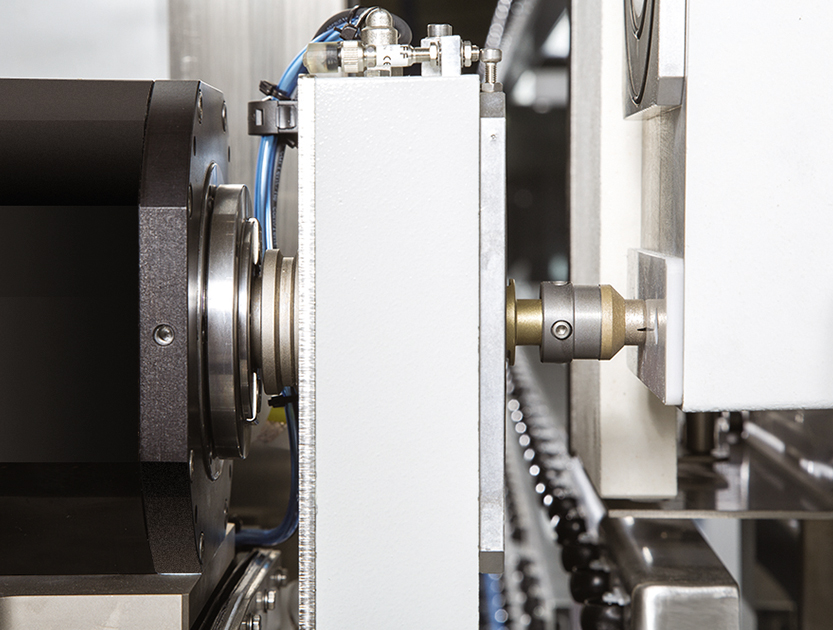

Accuracy and maximum positioning speed thanks to linear actuators on all axes that guarantee tolerances of +/- 0.15 mm at speeds up to 25 mtr / min. Very high precision electrospindles with ISO 30 cone that reach up to 10,000 RPM for maximum drilling performance. Pressurization system to prevent humidity and water return to the spindle chamber when the cone is released.

Automatic dressing and measurement of tool wear that can be activated manually or after a series of pre-determined holes. Automatic recovery of drill bit consumption.

Even more powerful and flexible software that in addition to the ‘drag & drop’ system, the ‘nested program’ and ‘double zero’ functions, already present on standard Quickdrill, includes the DCS (Dynamic Control System) working mode that dynamically adjusts the parameters based on the conditions of the drill bit, and if necessary launches the dressing cycle. With this exclusive function, each operator becomes an expert or the machine can work independently inside a robotic work island.

Rotatory tool holder with 8+8 positions, mounted on the spindle head for a tool change in less than 8 seconds.

Accuracy and maximum positioning speed thanks to linear actuators on all axes that guarantee tolerances of +/- 0.15 mm at speeds up to 25 mtr / min. Very high precision electrospindles with ISO 30 cone that reach up to 10,000 RPM for maximum drilling performance. Pressurization system to prevent humidity and water return to the spindle chamber when the cone is released.

Automatic dressing and measurement of tool wear that can be activated manually or after a series of pre-determined holes. Automatic recovery of drill bit consumption.

Even more powerful and flexible software that in addition to the ‘drag & drop’ system, the ‘nested program’ and ‘double zero’ functions, already present on standard Quickdrill, includes the DCS (Dynamic Control System) working mode that dynamically adjusts the parameters based on the conditions of the drill bit, and if necessary launches the dressing cycle. With this exclusive function, each operator becomes an expert or the machine can work independently inside a robotic work island.

Rotatory tool holder with 8+8 positions, mounted on the spindle head for a tool change in less than 8 seconds.

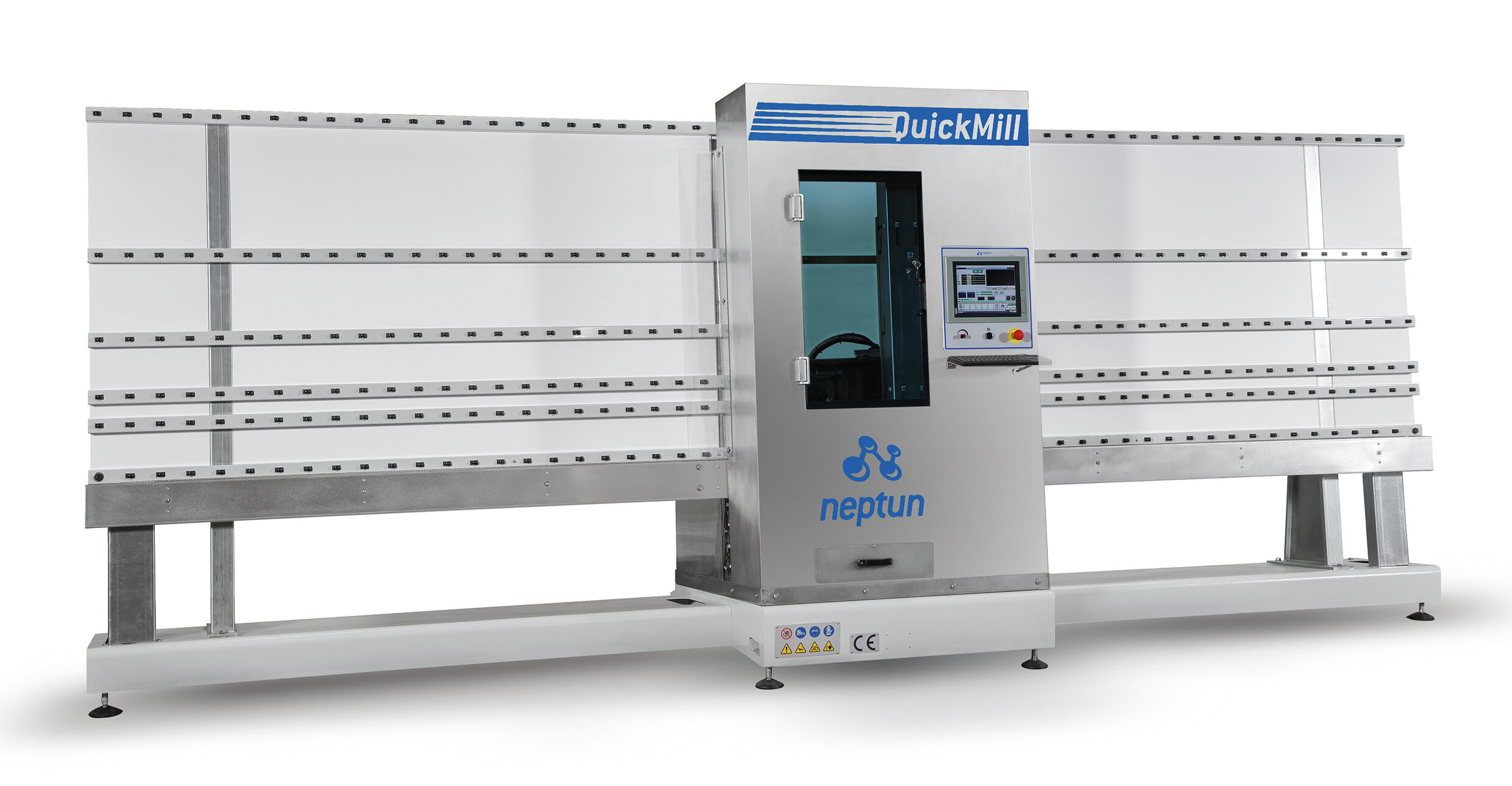

Quickmill 100-22

Single-head milling / drilling machine ideal for small to medium-sized companies, which require production flexibility without on-line integration with other machines. The drilling software that allows quality close to a traditional drilling machine is particularly appreciated. Built for industrial use and with performances that are close to the superior model, it has technical solutions that meet small budgets.

Still glass milling / grinding machining for higher milling quality.

Programming software simplified to the fullest for easy use even by non-expert operators of Numerical Control machines.

Simple and robust construction to provide maximum reliability even to small glassmakers without electro-mechanical professionalism.

Convenient drawer for extraction of processing residues.

Still glass milling / grinding machining for higher milling quality.

Programming software simplified to the fullest for easy use even by non-expert operators of Numerical Control machines.

Simple and robust construction to provide maximum reliability even to small glassmakers without electro-mechanical professionalism.

Convenient drawer for extraction of processing residues.

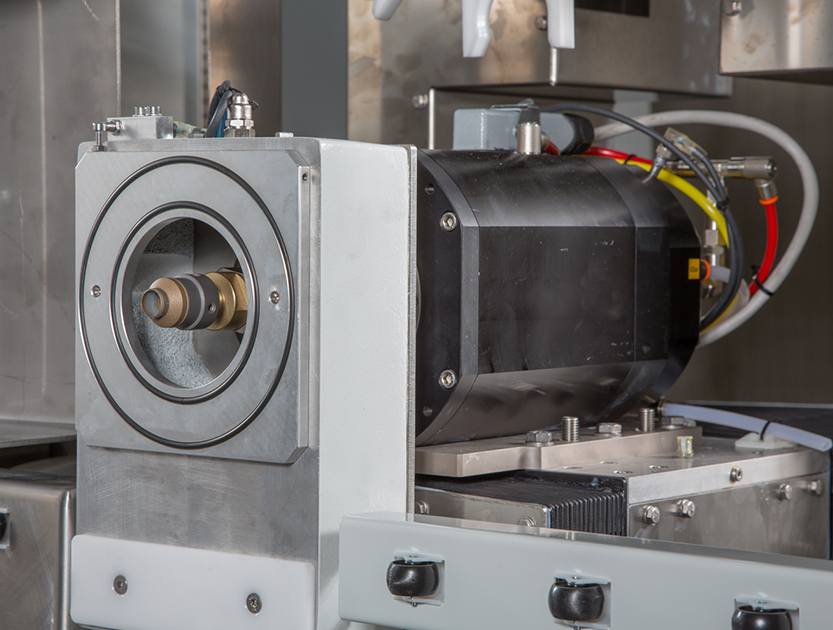

Quickmill 160-30

Uncompromising milling machine for notches and portholes, suitable for industrial contexts where high productivity, precision and the possibility of complete integration with other machines and company ERP is a must.

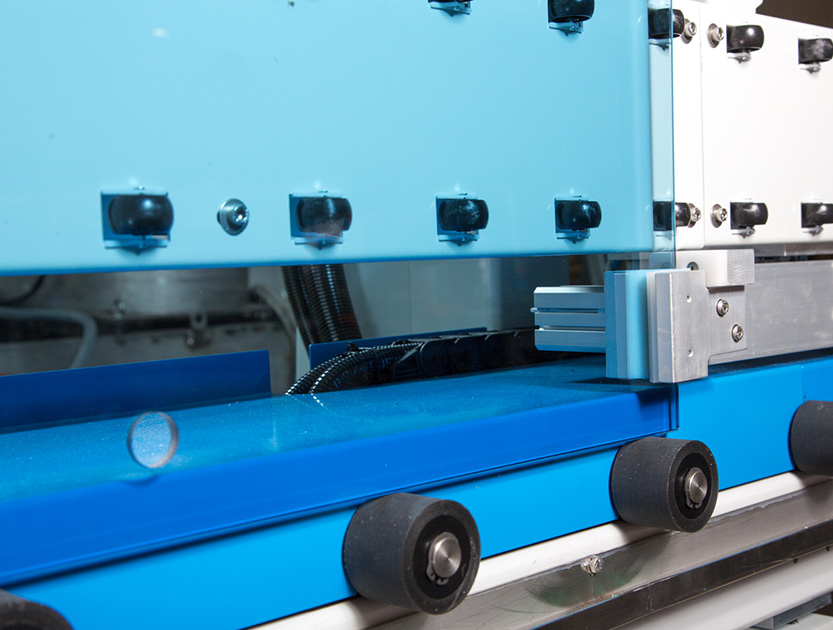

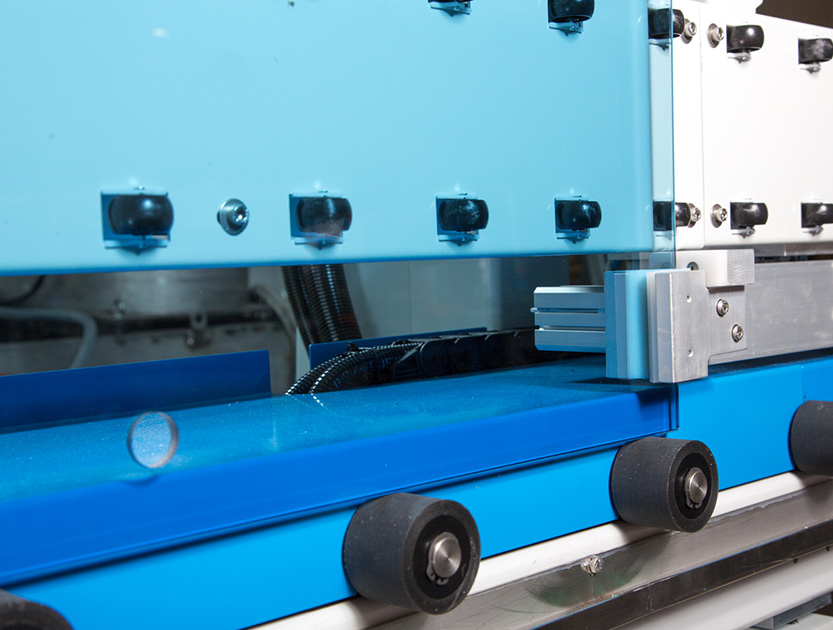

The still glass processing and the positioning of the suction cups always close to the work area allows greater milling speed and grinding precision, especially for threads, compared to models that move the glass.

The possibility of positioning the suction cup up to the maximum workable height of the glass eliminates vibrations compared to other models with blocking system from below, reducing the risk of glass plate breaking.

Parametric programming system with over 1000 shapes in memory of the most important world producers of hinges. Possibility to remotely program and import files with DXF or recall them with a barcode reader.

Tools of various types optimized for the required machining. Drill bits, mills, wheels, combi & triple tools.

The still glass processing and the positioning of the suction cups always close to the work area allows greater milling speed and grinding precision, especially for threads, compared to models that move the glass.

The possibility of positioning the suction cup up to the maximum workable height of the glass eliminates vibrations compared to other models with blocking system from below, reducing the risk of glass plate breaking.

Parametric programming system with over 1000 shapes in memory of the most important world producers of hinges. Possibility to remotely program and import files with DXF or recall them with a barcode reader.

Tools of various types optimized for the required machining. Drill bits, mills, wheels, combi & triple tools.

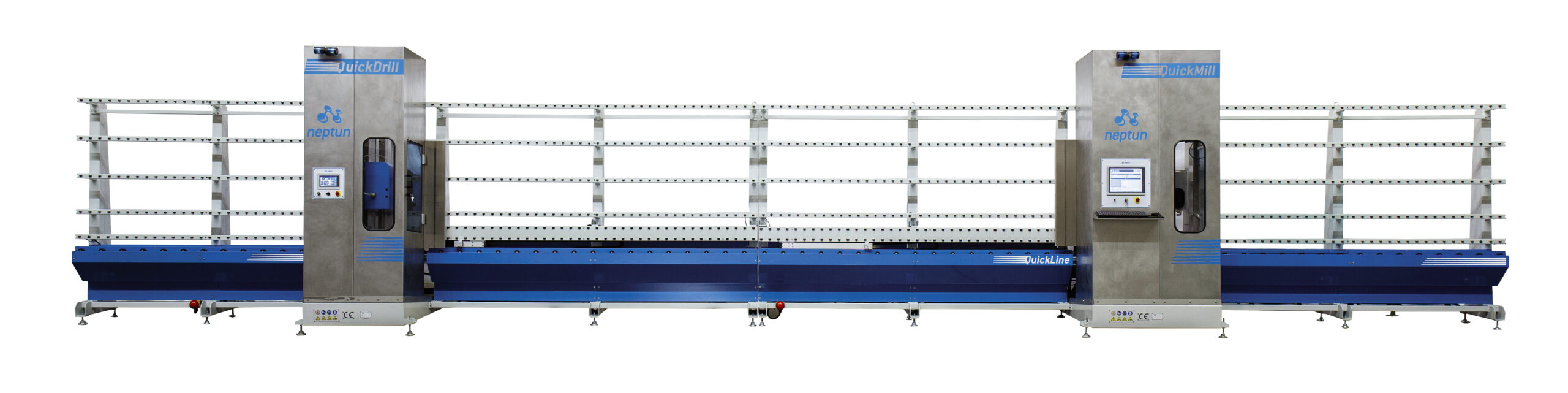

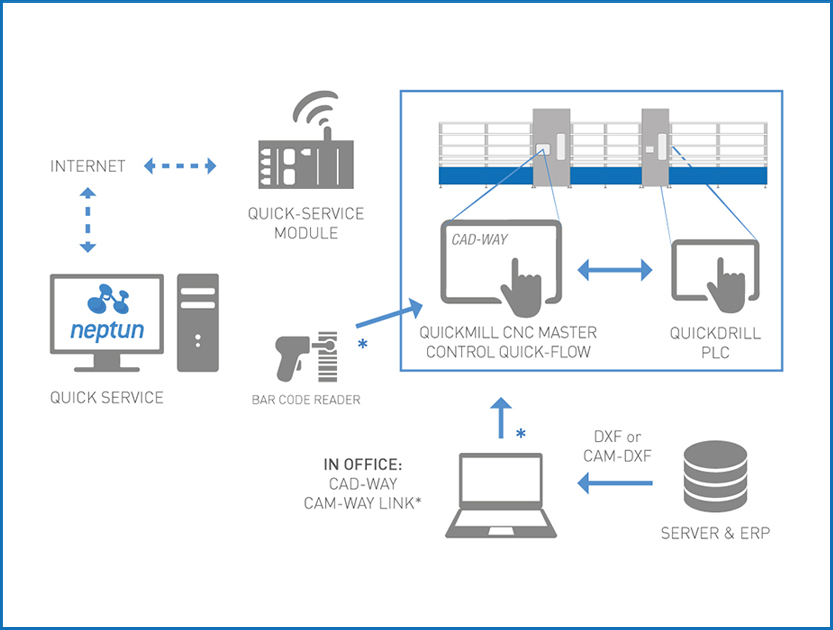

Quickline

Quickline is the in-line combination, even at different times, of the Quickmill 160-30 and one of the 2 Quickdrills. Ideal for the serial production of doors, shower enclosures, parapets and showcases of medium-large size. Quickline is required in production contexts 24/7, usually in line with washing machines and automatic loading / unloading where downtime, even short, are not tolerated.

Thanks to a powerful coordination software, the 2 machines can work in line or independently at the same time, providing maximum productivity (up to 15 doors/hour) and maximum working flexibility, with 2 different production batches processed simultaneously.

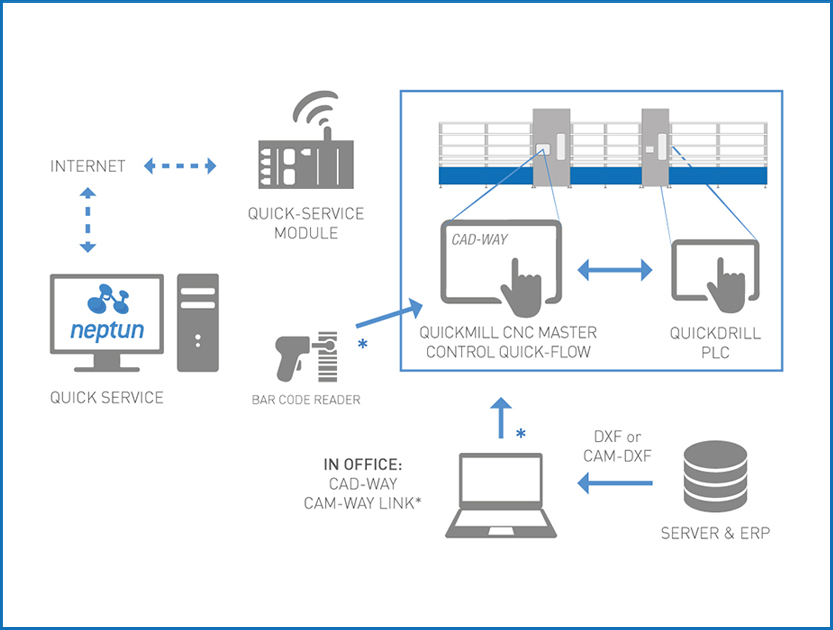

Although there is an optimal working direction, the line offers maximum flexibility of work direction and loading and unloading area, which can also be changed daily by the operator. In complete software configuration, it is possible to provide remote assistance via Quickservice, program from workstation in the office and / or recall stored programs via bar code until the line is integrated into the company management system, meeting the requirements of Industry 4.0

Thanks to a powerful coordination software, the 2 machines can work in line or independently at the same time, providing maximum productivity (up to 15 doors/hour) and maximum working flexibility, with 2 different production batches processed simultaneously.

Although there is an optimal working direction, the line offers maximum flexibility of work direction and loading and unloading area, which can also be changed daily by the operator. In complete software configuration, it is possible to provide remote assistance via Quickservice, program from workstation in the office and / or recall stored programs via bar code until the line is integrated into the company management system, meeting the requirements of Industry 4.0

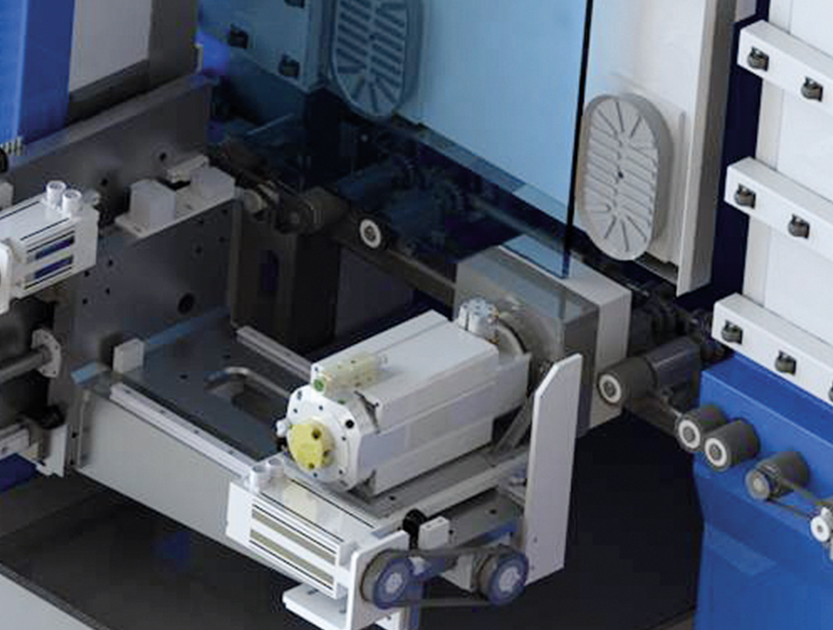

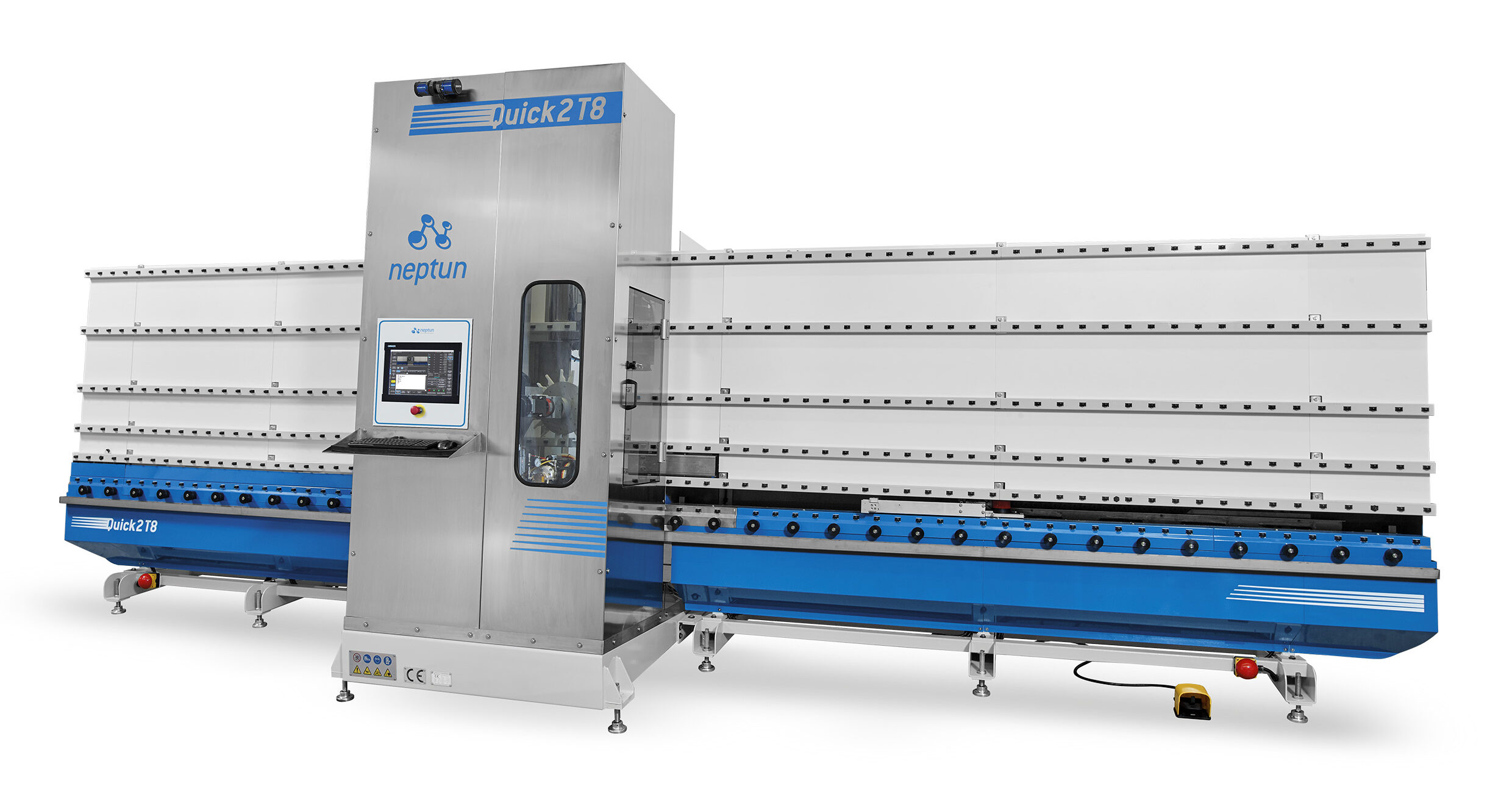

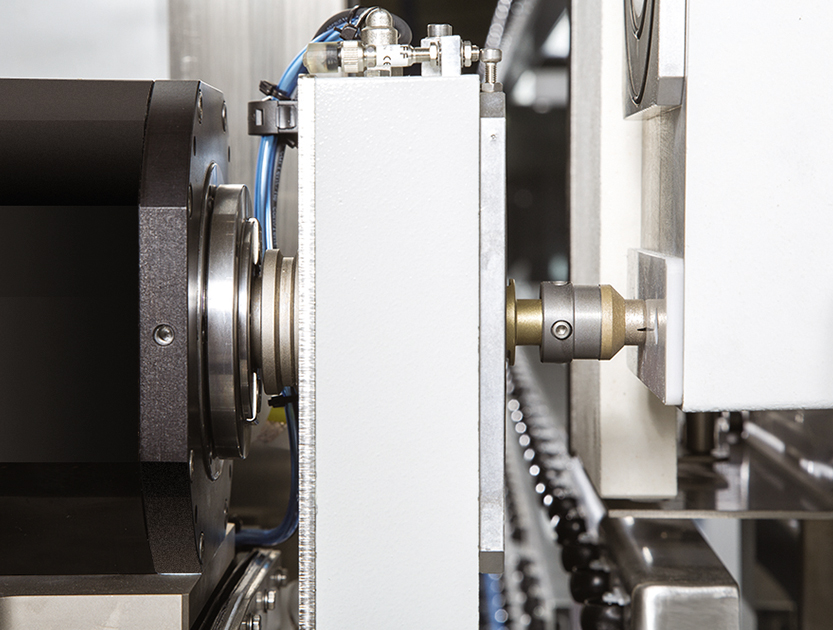

Quick2 -T8

the Quick 2 T8 is the top of the range for this process and combines the 2 phases in a single machine. Fully automatic drill/mill that maintains the benefits of the 2 top models in a single machine. Ideal for all companies that have an important and flexible industrial production but have to sacrifice something in productivity itself due to smaller spaces.

The drill function reflects all the benefits of Quickdrill including simultaneous tool change to the positioning of the axes for an execution time between one hole and another of different diameters of less than 8 seconds.

Glass movement at 25 mtr / min, with 0.15 mm positioning tolerance and a drilling speed of up to 4 mm second. The patented DCS system optimizes drilling performance based on the quality of the tool, and allows you to maximize results even for non-expert operators. Stopwatch in hand, the fastest drilling cycle on the market.

For the milling phase, we confirm the winning feature of still glass processing and the positioning of the suction cup always close to the work area. Optimal situation that allows higher milling speed and grinding precision, especially for threads, lower risk of glass plate breaking or chipping compared to competing models that move the glass.

Fast and precise milling and grinding processes, characterized by low-wear of mechanical parts thanks to the stationary glass and suction cups always positioned close to the working area.

The drill function reflects all the benefits of Quickdrill including simultaneous tool change to the positioning of the axes for an execution time between one hole and another of different diameters of less than 8 seconds.

Glass movement at 25 mtr / min, with 0.15 mm positioning tolerance and a drilling speed of up to 4 mm second. The patented DCS system optimizes drilling performance based on the quality of the tool, and allows you to maximize results even for non-expert operators. Stopwatch in hand, the fastest drilling cycle on the market.

For the milling phase, we confirm the winning feature of still glass processing and the positioning of the suction cup always close to the work area. Optimal situation that allows higher milling speed and grinding precision, especially for threads, lower risk of glass plate breaking or chipping compared to competing models that move the glass.

Fast and precise milling and grinding processes, characterized by low-wear of mechanical parts thanks to the stationary glass and suction cups always positioned close to the working area.

Perché scegliere Neptun

Because by listening and analyzing the needs of glassworkers, we have developed the greater range of vertical NC for drilling, milling and grinding worldwide.

Because, thanks to the expertise gained after hundreds of installations, we can suggest the best solution for your production needs.

Because we have four assistance centers in Italy and a fully stocked spare parts warehouse, to be close to you, and quickly, when necessary.

Neptun Quality

Our Numbers

years

countries

machines sold

%